scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

training course programhome profile consulting training events contact |

scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

training course programhome profile consulting training events contact |

This eye-opening simulation is now available on DVD. It consists of a high-quality video illustrating the differences between traditional "batch" production and continuous, one-piece-flow production.

This eye-opening simulation is now available on DVD. It consists of a high-quality video illustrating the differences between traditional "batch" production and continuous, one-piece-flow production.

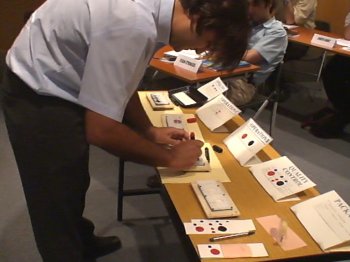

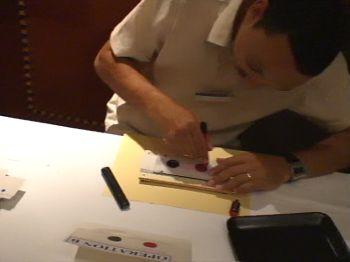

This simulation is regularly performed in all Lean Manufacturing and Lean Thinking real-world courses conducted by Carlo Scodanibbio. Participating delegates are involved in the simulation and play a role in it.

Without exception, delegates are thrilled by the light and entertaining style of this simulation, and consider it a tremendous eye-opener for anyone still sceptical about lean practices.

This DVD has been conceived as a train-the-trainer tool: it gives the trainer a powerful message to transmit to trainees with the purpose of sensitising them and generating a strong awareness about the need of switching over from batch production to flow production, while highlighting the numerous benefits of the latter.

As such, it's an ideal tool for Lean, in-house Training.

To see a low-quality preview of this video DVD click here.

If you wish to download to your computer a low-quality preview of this video in WMV (Windows Media Video) format right-click here (save object as...)

Many Manufacturing Enterprises are willing to undergo the "lean" road. Many enterprises make a formal decision in this respect.

Many Manufacturing Enterprises are willing to undergo the "lean" road. Many enterprises make a formal decision in this respect.

However, many enterprises just don't get there: their "lean" project gets somehow stuck midway, even at the very beginning - momentum decays or even gets lost altogether - the "lean" project gets postponed, delayed and even rescheduled indefinitely. Why?

For a number of reasons. One of the main reasons is that people (at all levels!) simply don't see the advantages and benefits of a style of production so different from the very familiar one they are used to from long time: the "batch production" style.

That's why this simulation could come extremely helpful:

During the two stages of the simulation (first: batch - then: flow) all relevant parameters are measured and then entered into a summary spread-sheet. A comparison is then possible and average benefits are as follows:

This training DVD consists of 3 main section:

- the actual simulation movie: 11 minutes of high-quality video

- a summary of the main production parameters collected during the two stages of the simulation, with comparisons

- guidelines for Training Facilitators

The movie is rather entertaining: the audience feels at ease and grasps very rapidly principles, concepts and benefits.

The movie is rather entertaining: the audience feels at ease and grasps very rapidly principles, concepts and benefits.

Training Facilitators are provided with guidelines to give high impact to the training session.

A Facilitator can easily guide the audience through the two stages of the simulation, pointing out: significant steps - snags and drawbacks typical of batch production that may go overlooked or ignored in real life in a real factory - how it can be possible that flow production can generate such incredible benefits compared to batch production. The Facilitator will also highlight the "morale" issue (how better and more satisfactory is for production people to produce in flow style rather than batch style).

The training Facilitator will also be enabled to point out limitations and constraints associated with Flow Production in real situations, mainly 3: labour-intensive operations - combination labour/light machinery - combination labour/heavy machinery.

The Facilitator can also explain the various pre-requisites necessary to gradually switch over from traditional batch production to one-piece-flow and continuous flow production.

This DVD, conceived to be a real learning experience, is ideal for "in-house" use.

This DVD, conceived to be a real learning experience, is ideal for "in-house" use.

Although the simulation and the DVD have been designed specifically for Manufacturers, attendees from other industries (project/construction - service establishments) will greatly benefit from viewing the origins of Lean Thinking as well as a practical pathway to lean processing in any industrial, commercial or business operations.

Heads and Directors of Operations, Quality, Maintenance and Production - Operations Managers, Production Managers, Production Planners and Supervisors - Lean and Continuous Improvement Champions and Team Leaders.

The cost of this Training DVD, including packaging and despatching by ordinary airmail parcel worldwide, is US$ 49,95 (equivalent to approx. Euro 39,00 and ZAR 500). Payment (bank transfer) can be made in any of these 3 currencies. Credit Card and Paypal payment can only be made in US$.

| If you wish to pay by Paypal or Credit Card and get this DVD despatched immediately to you please click on this button |

|

If you wish to pay by Bank Transfer or any other method, please contact Carlo Scodanibbio.

Upon receipt of your payment, I will despatch your DVD immediately and confirm Tracking Number by e-mail.