scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

home profile consulting training events contact |

scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

home profile consulting training events contact |

|

consulting

services training

services specials

reading

material resources

|

the world-class, lean performance formula".........in a rapidly changing world, featuring vanishing borders and hot, global competition, all Enterprises, including Small and Medium Enterprises (SME), can and should today perform operationally as the 'best in the classroom' by adopting the lean formula:"

major lean training programmes

|

|

Lean Management Training Program

Malta 2015  Lean Management Training Programme.

Lean Management Training Programme.A comprehensive suite of Lean Training Courses, Seminars & Workshops. For details click here |

Lean Management Training Program

South Africa 2015  Lean Management Training Programme.

Lean Management Training Programme.A comprehensive suite of Lean Training Courses, Seminars & Workshops. For details click here |

Tele-Training/Online-Training/Distance-Training/Webinars are a reality.

A) In-house Tele-Training. All training courses, seminars and workshops (view ») offered by Carlo Scodanibbio are readily available: just get in touch by email or phone (contact page ») and planning can start.

B) Public Webinars. Starting from September 2020, a number of Public Webinars will be available.

Just check this page for further announcements.

|

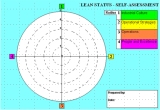

How "lean" is your Organisation?

Self-assessment Questionnaire  How far is your enterprise from "lean status"?

How far is your enterprise from "lean status"?# Are you just planning of going "lean"? # Have you just embarked on the "lean" boat? # Are you well advanced with "lean" initiatives and progresses? In all cases, this free Self-Assessment Questionnaire could give you lots of hints, tips, and food for thought... For details click here |

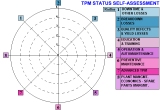

How far is your factory from TPM targets?

How far is your factory from TPM targets?

How far is your factory from TPM targets?# Are you just planning of starting a TPM implementation programme? # Have you already deployed some TPM and Autonomous Maintenance principles? # Are you at "TPM-Champion" stage? In all cases, this free Self-Assessment Questionnaire could give you lots of hints, tips, and food for thought... For details click here |

|

Special Offer to all SMEs world-wide

Show the waste to your people!

Show the waste to your people!If you are interested in organising an "in-house" (at your premises) Training Course with a duration of 3 days (24 hours) or more, you will get an extra day of my time (at no charge) to show your people your own "in-house" waste. How? Through my video-camera..... For details click here |

Free Tele-Consulting

The first tele-consulting service (via Skype or by Email) is free to all SMEs world-wide and to all participants in my past courses.

The first tele-consulting service (via Skype or by Email) is free to all SMEs world-wide and to all participants in my past courses.

Just fill a simple form or send me an email with your request for assistance. NB: my free intervention can only be on a specific rather than generic problem. Get it now - for details click here |

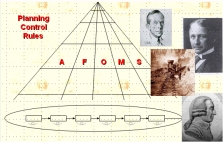

""...the end of the Smith & Taylor Scientific System...""

""...the end of the Smith & Taylor Scientific System..."" World-Class Manufacturing

World-Class Manufacturing Lean Project Management

Lean Project Management Process Improvement & Management

Process Improvement & Management Total Employee Involvement

Total Employee Involvement Lean Kaizen (continuous, step-by-step improvement in the Lean direction)

Lean Kaizen (continuous, step-by-step improvement in the Lean direction)

Acknowledgement

Clipart and Media Material in this page, with thanks to:

Dreamstime

FreeDigitalPhotos and their Authors:

Bugphai

Danilo Rizzuti

Franky242

JScreationzs

Phaitoon

Sheelamohan

Suwit Ritjaroon

Tigger11th

Ventrilock

giancarlopagl.wordpress.com

Guidecucina - Pianetadonna

J. Barta & Boris Vallejo