|

navigation

consulting

services

training

services

specials

reading

material

resources

|

All my articles are available at no charge for publication in Newsletters, Bulletins, Magazines, etc. on condition that credit is given and a link to this web site is provided. For further details, please contact Carlo Scodanibbio.

Lean Thinking and Load Shedding in South Africa

by Carlo Scodanibbio January 2023

From a few years already, a new wording is becoming more used and popular in South Africa: "Load Shedding".

WHAT IS LOAD SHEDDING

Load shedding is a measure of last resort taken by Eskom (South Africa's largest producer of electricity) when power demand begins to exceed possible supply. To avoid a nationwide blackout and total collapse of the power grid, Eskom rations the available supply between different districts according to a published schedule. (Source: Bing.com)

So, Load Shedding means that - at certain, pre-planned times of the day or the night - the Mains Power Supply is cut-off, or disconnected, for a duration of approximately 2 hours, to private, commercial and industrial dwellings; in pre-planned areas of the Country. This may happen once, twice, three times and even 4 times a day. According to a well-conceived schedule, that:

# Takes into consideration available supply and demand in any given area or district

# Accordingly, sets a plan to ration the available supply to each area or district

# In a spirit of justice or fairness, i.e. without penalizing any area or district - in rotation throughout the day

According to Scout Africa (https://scoutafrica.net/load-shedding-in-south-africa/):

"""

Load shedding is an energy utility's method of reducing demand on the energy generation system by temporarily switching off the distribution of energy to certain geographical areas.

South Africa has experienced load shedding since 2007 because the country failed to build new power stations to keep up with economic growth and replace ageing generation plants.

Load shedding is aimed at removing load from the power system when there is an imbalance between the electricity available and the demand for electricity. If we did not shed load, then the whole national power system would switch off and no one would have electricity.

Why is shedding load necessary? Shedding load is required when the demand for electricity approaches supply, creating the potential for a dangerous imbalance. It's a way to help reduce power demand by turning power off to some customers to help prevent longer, larger outages.

The planned schedules ensure that available capacity is shared fairly and each consumer gets power at one time or another.

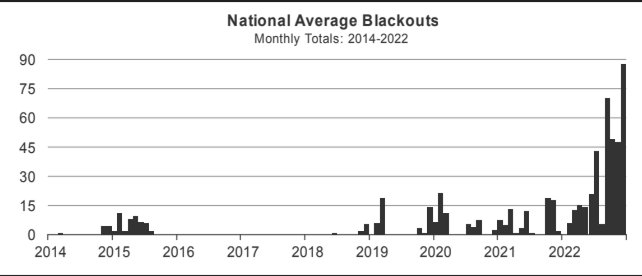

South Africa experienced over 150 days of load shedding in 2022, up from 75 in 2021 and 54 in 2020.

Analysis by Eskom Research, also shows that, besides 2021, there were more power cuts in September than had been experienced in any other entire year since load-shedding started in 2007.

"""

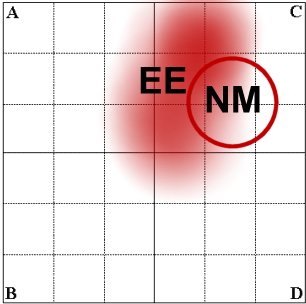

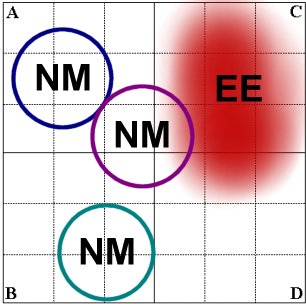

According to BusinessTech (https://businesstech.co.za/news/energy/658345/eskom-clarifies-permanent-load-shedding-for-south-africa/), this has been the recent trend:

"""

"""

According to Generator King (https://www.genking.co.za/news/the-economic-consequences-of-load-shedding-in-south-africa-and/):

"""

An energy expert has estimated the cost of controlled blackouts in South Africa and highlighted the serious negative economic impact thereof. Stage 1 (see below) load shedding resulting in 10 hours of blackouts per day for 20 days a month results in losses of R20 billion per month. Using the same time parameters, Stage 2 (see below) load shedding costs the economy R40 billion per month and Stage 3 (see below) is estimated to cost the South African economy R80 billion per month. These costs, according to Yelland, to the productive economy are based on a cost of unserved energy of R100 per kWh. When one considers that the approximate GDP of South Africa in 2014 was R4 trillion approximately 1-2% of GDP could potentially be wiped out per month of load shedding.

"""

The above is the picture of Load Shedding in South Africa.

It's not within the scope of this Newsletter to analyze the causes (not planning in due time the provision of new power stations? Poor maintenance of the existing power system? etc.) of this rather worrying situation and to describe its impact on industry, businesses, and the man in the street.

The scope of this Newsletter is to discover if - by applying Lean Thinking approaches - a solution to the problem may be found in the medium term.

To the purpose I need to describe some more features of the Load Shedding issue.

THE LOAD SHEDDING SCHEDULE - THE STAGES

According to Softbacktravel (https://softbacktravel.com/what-is-load-shedding/#:~:text=Load%20shedding%20is%20a%20measure%20of%20last%20resort,between%20different%20districts%20according%20to%20a%20published%20schedule.):

"""

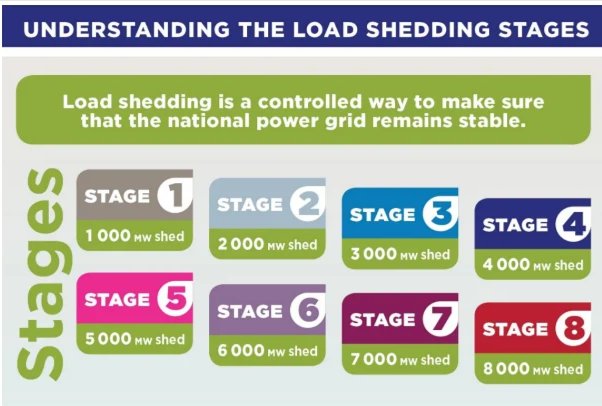

As of 2020, there are a total of 8 Load Shedding stages. The higher the stage, the more frequently one would experience electricity cuts.

The stage is determined by Eskom and depends on the number of megawatts needed to balance the power grid.

Once a schedule has been agreed upon, Eskom and the municipalities implement the load shedding plan on a rotational basis.

Load shedding will then commence for 2 - 4 hours at a time, depending on the stage and also on the area. For example, in stage 8 power will be turned off throughout the day for a total of 12 hours.

"""

Rather complex, isn't it?

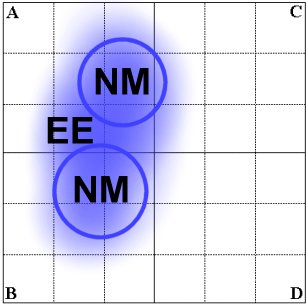

Let me go into further details. Now, according to my interpretation of this complex schedule:

# Eskom and local Municipalities in each District, agree on a certain Stage for a certain day (or part of that day)

# And for each day of the months ahead, they provisionally assign a Stage to a certain interval of time (theoretically: 2,5 hours - in practice: +- 2 hours of power off ) of each day.

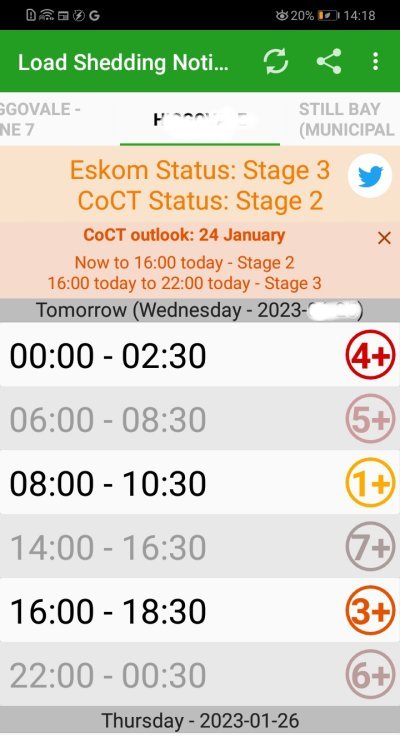

# For instance, in the area of Cape Town in which I live, in a typical day of January 2023 the Stage Schedule might be as follows:

° 00:00 - 02:30 Stage 4+

° 06:00 - 08:30 Stage 5+

° 08:00 - 10:30 Stage 1+

° 14:00 - 16:30 Stage 7+

° 16:00 - 18:30 Stage 3+

° 22:00 - 00:30 Stage 6+

# Each Stage (except Stage1), includes lower Stages

# So, Stage 5 for instance, would include Stage 4, Stage 3, Stage 2 and Stage 1

# So, in the typical day above: if the Stage of the Day for my area is Stage 3, I would get no power between 08:00 and 10:30 (because Stage 1 is lower than Stage 3) - and between 16:00 and 18:30 (because it has been assigned Stage 3)

# But if in the typical day above the Stage for my area would be Stage 7 (or 8), I would get no power for 6 intervals of time that day, for a total of 12 practical hours out of 24 in the dark!

Here it is, what follows is a screenshot of a Load Shedding Notifier for my area in a typical day:

Got the concept?

Now: how does the man in the street know about any day's schedule?

Either browsing the web: Eskom web site and others - or installing a fantastic App on his mobile phone!

There are 2 Apps that I know of (there may be others), and they can be downloaded from Google Play Store: one is called EskomSePush and the other Load Shedding Notifier. I use both. Both can be set to know in advance the Load Shedding Schedule for your area, and for all areas in South Africa!

And you can share by WhatsApp your Schedule or any Schedule with friends, etc. Magnifique!

LEAN THINKING CONSIDERATIONS

My dear friends, think aloud with me (lean-think!):

The scheme illustrated above is a super-star-galactica plan!!

Just imagine how many people, over the years have been squeezing their brains and dedicating their best energies (and time) to: conceive, preliminary-design, modify, final-design, and put into action such a scheme. Inventing Stages and time slots, on the basis of past, actual and projected power demand, per province, district and area, and without penalizing any area! Both at Eskom and at all Municipalities in South Africa.

Dozens? Hundreds? Thousands?

And how many people are required, on a daily basis, to make the scheme work operationally, adjusting it in-real-time? We don't know...

(One note about adjustment in real time: yes, because today's Load Shedding Schedule may differ from what was appearing yesterday and even half an hour ago in the App schedule: this moment Stage may change all of a sudden… this happens, even at no notice, and you may find yourself without power at any unpredictable time!! C'est la vie, as they say in France...)

And how many people are taking care of switching power OFF and ON at hundreds (thousands?) of electrical sub-stations country-wide?

I have no idea. And I have no idea if the switching OFF/ON is done manually - by human beings - or electronically, via a computerized control system... and I don't even want to know...

However, in the first instance (manual switching OFF/ON) there must be hundreds of people who physically operate circuit breakers at electrical sub-stations. And since the interval between OFF and ON is approx. 2 hours, most probably they will need to be there on a full time basis, waiting for instructions, and during load shedding doing absolutely nothing? I don't know, and I don't want to know...

OR, if the OFF/ON operations are controlled via a super-star-galactica computerized system, how many people have been and are involved to: design it, launch it, maintain it, adjust it, modify programs, etc. etc. ???

This goes beyond my wildest imagination...

And how many efforts, people and time have been dedicated to create the Load Shedding Apps, and to update them, and... I don't know, and I don't want to know...

All I know is that there must be a tremendous amount of manpower dedicated to Load Shedding operations, which is completely WASTED!

Yes, WASTED, because under the Lean Thinking angle of view, whatever does not generate value to the client (all private, industrial and public users of electric power) it is pure, solid WASTE.

Even worse: not only there is no VALUE to clients generated by the Load Shedding concept, but clients are penalized, harassed, and very annoyed by it!!!

NOT LEAN - AT ALL!!

Even worse: since

# The OFF time is unpredictable: if it is scheduled at 10:00 am, power may be OFF at 10:00 - or at 10:02 - or at 10:05 - or at 10:12 - or at 10:15... and, sometimes (very seldom) power does not even go off (a grace from Heaven...)

# The power back time is also unpredictable

# And, most detrimental (as described above), the power OFF time may come out at none or little notice!

And the poor man in the street must adapt, change lifestyle, plan and think ahead! He must decide what is the most convenient time to cook and have supper, for instance, if there is Load Shedding at his preferred supper time and he has no gas stove... The same for breakfast, and lunch... And he must be careful when taking a shower in the evening (or during any time of the day if his bathroom has no windows) to prepare a torch or an emergency light nearby, otherwise he won't even find his towel when getting out... And what about charging laptops, tablets and mobile phones? A nightmare: you need your battery to be alive when you need it; on the other hand, you don't want to overcharge it, which may prove detrimental to the battery's life... even worse if your battery is half dead... Oh Boy, oh boy, oh boy...

What do you call that, for the poor man in the street? TERRORISING, that's the right name!

Enough is enough... So, let's see if there might be any LEAN solution to this problem.

LEAN SOLUTIONS?

My dear Readers, I believe any technical or technological solution to this problem is beyond my capacity (although my background is Electro-Mechanical Engineering) and your capacity (even if you are a brilliant Scientist...). Surely, you may argue, the solution would have been to build more power stations in due time in due course... But that's too late... and planning to build power stations now is simply pure and tardive speculation...

BUT, please think (LEAN-THINK) aloud with me, and let's recall the wider LEAN Motto: Lean-Mean-Green.

Some Considerations:

# They say ( https://energypost.eu/10000-sq-km-of-solar-in-the-sahara-could-provide-all-the-worlds-energy-needs/ ): "10,000 sq km of Solar (panels) in the Sahara could provide all the world's energy needs" - or, "All the world's power could be provided by a square 100km by 100km area in the Sahara."

But (https://www.weforum.org/agenda/2020/01/solar-panels-sahara-desert-renewable-energy/) "Solar panels reflect less heat back into space compared to sand, which could change the region's climate - and make it rain more."

# How many Sq Km of solar panels in the Karoo desert in South Africa could provide sufficient energy for the entire Country? I don't know, and I don't want to go into complex calculations (such as world's and South Africa's GWh or TWh per year...), nor you would like such calculation. Most important, we don't need it. But, for the sake of speculating, maybe 100 Sq Km would do? Or maybe 300? Never mind, it's not my intention to propose to install 10x10 Km of solar panels in the Karoo! It may be detrimental to local climate, and the investment required might be out of proportion for the South African economy...

# Instead, I would like to tell you a small story: I have been living (part-time) in and operating from the tiny island of Malta, in the Mediterranean Sea, south of Italy, for many years. One of the wisest decisions I have ever made was to install a solar water heater and photovoltaic solar panels on the roof of my property. Thanks to an "incentive scheme" set by the local MRA - Malta Resource Authority, part financed by the European Regional Development Fund. This is what happened over many years:

# With regard to the Solar Water Heater: after submitting the necessary application to the MRA, which was timely approved, I received a 25% grant amounting to 25% of the total installation cost. Then I had hot water for the entire dwelling for years, and had to switch on the electric geyser maybe 5-6 times in many years, only in winter. I guess my investment was repaid in a matter of 2 years...

# With regard to the Photovoltaic Panels: the MRA Scheme was launched in 2010 (and is still active today - see https://www.rews.org.mt/#/en/sdgr/463-2021-renewable-energy-sources-scheme-active), and soon thereafter I made my application, which was timely approved. The MRA Grant amounted to 50% of the total installation cost (panels, stands for panels, inverter, batteries, connections, etc.). Very good, and it was timely refunded into my account after the installation was completed. With 8 solar panels on my roof, I had plenty energy for my house. But that was not all. The MRA Scheme catered for private solar systems to be connected to the "grid" (the public electrical network) and "feed-in" into the grid, selling all excess-generated power to the local Electricity producer, called Enemalta (the equivalent of Excom in South Africa)!!!! Listen to this: you have solar panels on your roof - you use the power generated by your panels during day and night (thanks to inverter and back-up batteries) - if the power generated by your panels is not sufficient, automatically you "buy" power from the "grid" and you pay 16 cents of a Euro per KWh (per Unit) - but if the power generated by your panels is in excess of your instant consumption, automatically you "sell" excess-power to the "grid" and you are paid by Enemalta 25 cents of a Euro per KWh (per Unit)!!!!! HAHAAHAHAH!!!!! THAT'S A GOOD SCHEME!!!!

# In my case in Malta: since the water and electricity Bill is one, issued by ARMS (Automated Revenue Management System) on behalf of Enemalta (electric bill) and WSC (Water Services Corporation, for the water bill) - and since with 8 solar panels I had a lot of excess power to be fed into the "grid", over the years I have not been paying a single cent for water and electricity!!!! My ARMS account was always in credit, and actually - when eventually I sold my Malta property recently - my final credit (100s of Euro) was paid back timely to me by ARMS!!!!

YEAHAHAAHHHH!!! THAT'S A "SCHEME"!!!!!!!!!!!!

Think (lean-think) aloud again with me:

# "Malta enjoys around 3,000 hours of sunshine per year (also one of the highest in Europe), from an average of above 5 hours of sunshine per day in December to an average of above 12 hours of sunshine per day in July." (Bing.com)

# "Most areas in South Africa average more than 2 500 hours of sunshine per year, and average solar-radiation levels range between 4.5 and 6.5kWh/m2 in one day. South Africa sees on average between 1543 - 2264 kWh/m2 a year. Simplified, this translates to 4.1 - 6.3 peak sun hours a day, with the Northern Cape experiencing the higher end of that spectrum and Kwazulu-Natal seeing the lower end. Having at least 4 hours of peak sunlight is best for solar panels." (SAFacts - https://safacts.co.za/average-sunlight-hours-in-south-africa/#:~:text=Average%20Sunlight%20Hours%20In%20South%20Africa%20Most%20areas,year%20round.%20Average%20Sunlight%20Hours%20In%20South%20Africa)

# So, compared to Malta, there is still well enough sunshine in South Africa to go for solar power.

# "Malta has four electricity plants operational and the total combined nominal installed capacity is 537.8 MW. The Malta-Sicily Interconnector, which has been in operation since April 2015, allows for an electricity link between the Maltese Islands and the Italian electricity market has bidirectional flow capacity of 200 MW." (Bing.com). No new Power Station has been built - that I know of - in the past 15 or 20 years. Which means that - over the years - Malta has been self-sufficient with the installed energy capacity; possibly (or most probably) thanks to solar installations along with the MRA Scheme!!!!

# Would a similar Scheme work in South Africa and cater - in the medium term - for reduction or even elimination of Load Shedding???

# Presently, South Africa has a Tax Incentives Scheme (rather complex) that caters for tax reduction upon installation of a solar system, under very strict conditions... But only for Business Taxpayers...

# And there is a tweet (only a tweet...) in which SA President announced the possibility of a "feed-in" scheme (something similar to the Maltese one...). When? No-one knows...

My dear friends and readers, it's not up to me to give technical/financially-viable solutions. Beyond my capabilities...

But let's lean-think aloud once more:

# The main secret to reduce and finally end load shedding is possibly: solar - with an appealing cash grant - with an attractive feed-in scheme, as appealing as possible - open to everyone (including pensioners who don't pay taxes, for instance)...

# If such a scheme would come out soon, crisp and clear, the majority of SA business and private entities would go along with it, I am pretty confident about...

# The massive investment required to install enough solar energy as fast as possible - possibly excessive for the troubled SA economy - would be shared between the public and the private/business sector...

# In a matter of 2 years things could progress extensively

# In a matter of 5 years the load shedding issue might be memories of the past...

# And should there be excess power generated by solar installations if the Scheme would become very popular, what would happen?? No problem: just switch off some generators in Power Stations here and there, isn't it?

In this way, finally, all presently wasted resources would then be dedicated to the real Lean target: generate VALUE for their Client - instead of penalizing and harassing them...

All the best my friends, keep well, and have a wonderful, Lean year 2023! (Lean-Mean-Green!!)

download this article

|

In a Lean environment Technology comes only third

by Carlo Scodanibbio January 2023

When I am in one of the Countries in which I spend a few months a year, I don't have Wi-Fi at home: so, I use one of my mobile phones as a "hotspot" to create a Wi-Fi signal in my entire house.

That phone is used only as a hotspot: it has no other use. So, it only consumes Mb or Gb of Data, that's all.

Obviously, I need to buy data for that phone from a local Mobile Telephony provider. Let's call them Dovanoc.

Now - as I do with all providers I use in several Countries - I check regularly my usage: residual credit, data used, data balance, etc. Just in case...

So, one blooming day, I discover that my Air Time Credit decreases of Local Currency X30 (approx. 1,8 USD) every day....

I try to call Dovanoc Customer Care: impossible!

No-one answer the call, whichever Menu option I choose. All I can do is to talk with "Boti", their Digital Assistant: a digital chat via SMS (free SMS!!!).

Digital Chatting is simply absurd: Menus, choose from 7 items, wait, tap on the phone keyboard like mad, yell digitally... a horrific experience!

Eventually, using all the patience in this world, after 40 minutes of chat I manage to understand that there is an active subscription to Game Lords (??&%$£?#?), that so far has eaten X120 of my air time credit.

Obviously, I never subscribed to Game Lords... Generally, I simply cancel and throw away the 4 or 5 promotional or marketing SMS that land in my phone almost daily... Possibly: one of these messages was conceived in such a way that if you DO NOT REFUSE A SUBSCRIPTION, IT WILL AUTOMATICALLY SUBSCRIBE YOU? I don't know...

Again, fighting digitally with the digital monster, and going through absurd menus, I manage to cancel that subscription! Confirmed by Boti!

But not to get refunded of my X120 - which is not a significant amount of money. However, purely as a matter of principle, I want my stolen air time back. Full stop.

So, I drive to a Dovanoc outlet. I explain the story to a lady, and she tells me that she needs my hotspot phone to call Dovanoc Customer Care, since only Customer Care can authorize a refund.

I don't have that phone with me, it's at home.

And, also, I explain the lady that it's impossible to talk to Customer Care.

She very calmly gives me the Customer Care number and states that - if I do not select any menu but just wait - eventually I will be able to speak to someone to claim my stolen credit back.

Hhhhmmmm, that I didn't try... So, let's try...

I go back home, and I try to call Customer Care: impossible!

After waiting and waiting, and after repeating the menu twice, the call is closed... Now I am furious!

So, I go back to the Dovanoc outlet: now there is another lady. I explain again my full story, and now I have my phone with me.

The lady, very kind, says she will call Customer Care with my phone on my behalf: because I MUST TALK WITH CUSTOMER CARE AND CLAIM MY CREDIT BACK!

Very well, I say. So, she calls Customer Care. But after 40 minutes of trying and trying, no joy... She cannot manage to get through...

At this stage, I almost lose my temper, and start using my loud voice in a loud way, as the situation deserves. There are quite a number of people in that outlet, and I can see they look at me with great sympathy and almost applause...

The lady understands the message. She calls Customer Care from her phone AS A CONSULTANT (sigh...)! And after 10 minutes of talking an un-understandable language, she manages to get my refund! An SMS arrives promptly to my phone: your air time has been credited with X120, regards (!!!). Oh Boy, oh Boy, oh Boy! DONE!

So, I thank and praise the lady loudly, and ask her 2 more things:

# Does Customer Care have an email address? The answer is NO

# So how do I call them or communicate with them? The answer is Boti!!!

And I ask her 1 more thing:

# Yesterday I recharged my air time with X200, so I received an SMS stating that - as a reward to be such a loyal customer - I had X200 of free calls for the day. A message that I normally ignore. But yesterday I decided to avail myself of this special bonus. I have called this local number, and my air time credit has gone down... Why? And how much did the call cost? The lady checks my records, the call costed X40. Hah hah, and what about my free X200 air time Bonus? The lady: No, that is not a Bonus - first they charge your air time.... and only when the air time is depleted, they give you free calls... sigh.... Now I use my loud voice again: "but this is pure fraud!!!"

The lady, silently, agrees... In the outlet everyone is listening to our conversation with horrified faces...

This is my Dovanoc story.

Quite sad, but quite enlightening.

Because this kind of things should not happen, but they happen more and more.

And the story is not over... listen to this!

Less than 3 weeks after the first chapter, all of a sudden, I discover that X15/day are disappearing from my air time credit!

Furious like never, I start another chat with Boti, and digitally yell and scream for this new episode of violence. And discover that there is a new active subscription, this time to Mobio360 (??&&$$%$£??). And by yelling and screaming digitally, eventually I manage:

# To cancel this new subscription

# To get called by a human being!!! (a new option that suddenly appears to me in my chat with Boti)

So, a human being from Customer Care calls me! Unbelievable!

Pointless to say, this time I can yell and scream in a human, non-digital way to someone!

# I manage to cancel all my active and future subscriptions, forever and ever - then confirmed by a subsequent SMS!

# I manage to STOP once and forever receiving any promotion, marketing or whatever else SMS from Dovanoc. I am pretty clear: all I want is SMSs confirming my air time recharges, and SMSs informing that my Data are decreasing or almost exhausted.

That's all! Also this request of mine is then confirmed by a subsequent SMS!

# And I manage to get refunded of X30 (15 +15, over 2 days of Mobio subscription).

This last point, is very intriguing: because the SMS I receive, confirms that I have been refunded not of X30 but rather of X150!!! Why? Mistake! The useless, digital bureaucrats refunded me also for the previous X120 of the first part of this story for a second time!!!

Did I complain? NO. Did I inform them I was over-refunded? NO!!!!! Because useless bureaucrats deserve a moral punishment. And I do not feel dishonest - at all - if I scored X120 (a few $). Well done, Carlo!

So, let's come to very simple conclusions.

Surely, Dovanoc are not LEAN. At all! Just imagine - apart from the over-refund of X120 to me - how much this entire story costed to:

# Me, first of all. Me, the customer: frustrations, aggravations, loss of temper, hyper-cholesterol, time, 2 visits to their outlet, etc. etc.

# Them. Their consultants' time wasted, their system filled with digital chats…. And - most important - their loss of reputation! Not only at their outlet, with a dozen people sympathizing with me for my yelling and screaming... But also through this newsletter: I have thousands of subscribers in the Country I am referring to, and it does not require a strong effort from them to understand who Dovanoc are in reality...

Which leads to the well know Lean Principle. IN A LEAN ENVIRONMENT:

1) People come first. Where People are Clients and internal Personnel.

2) Methods come second: Lean Methods! (maximum Value to Customers with minimal or zero internal processing Waste...)

3) Third, and only third, comes Technology.....

Surely, when the above priorities go lost or get mixed up, we face a disaster - especially when Technology (digital or non-digital) comes first, forgetting that there is a Monster Client out there waiting for Value, Value, Value...

download this article

|

Covid-19 and Edward De Bono's 6-Thinking Hats

by Carlo Scodanibbio December 2021

I am pretty sure you are, like I am, rather bothered after almost 2 years of pandemic - or Covid-19.

In France they say: "c'est la vie"... In English they say: "that's life"... In Italian we say: "la vita è così"... As if to say: "what can we do?"

It's not up to me - nor it is my intention - to say what we can or could do. It's simply beyond the scope of this message.

However, what comes to my mind - and I wish to convey it to yours - is how well (or how bad) the world (yes: the world) has deployed Edward De Bono's famous 6-Thinking-Hats approach to this very specific issue.

Let's just come to the point, the following are my views:

WHITE HAT

WHITE HAT

White Hat stands for: facts and figures.

Well: do we have, do we get, do we really know facts and figures about Covid-19?

You may say: we have plenty facts and figures. We have daily statistics, graphs, cases, deaths, intensive care, vaccinations (1st - 2nd - 3rd dose...), 1-week average, 30-day-average, 6-months-average, 1-year-average, and... and cases per million people, and incidence rates, and positivity rates, and dozens of other rates....

So, you may say, we have facts and figures.

Do we?

Are we sure?

Can we trust them?

No further comments, for the sake of being concise.

BLACK HAT

BLACK HAT

De Bono's Black Hat stands for: Negative Thinking, Judgmental Thinking...

The Black Hat has been widely used - in the past 2 years - to let us know (through all the media): how bad, how dangerous, how detrimental (to say the least) this Covid-19 Virus is.

Media has pumped into our eyes, ears and brains, images/stories/opinions, etc. etc. of people dying, or getting there, or just surviving, or being "ventilated", or..... (the list could be very long)....

AND: if you don't wear a mask.... if you don't wash your hands... if you don't maintain a "safe distance"... if you get into "gathering".... or, if you go to a funeral, a wedding, a celebration..... and: if you don't get vaccinated.....

Bad, very bad, terrible, horrific, terrorising, etc. etc.

Black Hat has reigned. Very effective use!

YELLOW HAT

YELLOW HAT

The Yellow Hat stands for Positive, look-ahead Thinking.

Hardly used. Except by Politicians, Head-of-State, illuminate Scientists, illuminate Thinkers, and so on, to express: no worry, we shall overcome, it will be better, it will disappear, economy will recover, GDP will grow.... and similar nonsense....

Effective use?

RED HAT

RED HAT

De Bono's Red Hat stands for: feelings, sensations and - in general - Emotional Thinking.

Widely used in the last 2 years by everyone: from top-level Entities to men-in-the-street, from pro-vacs to no-vacs, etc.

To express: bad, not so bad, could be worse, it's OK, it will be better, it will be worse, it will never end, it will end in 3-months, in 2022 it will be over, take it easy, look ahead, think positive, take these tablets and you will overcome depression, etc. etc. etc.

But, most important: get your vaccine! be vaccinated! get your second, third, nns dose, do it now.... the vaccine is the only way out! etc. etc.

OR: what vaccine? No vaccine! It's a commercial enforcement! It's a monopoly, a domination, dictatorship.... etc. etc.

The list could be infinite......

Very effective use!

GREEN HAT

GREEN HAT

The Green Hat stands for: imagination, ideas (valid, effective, problem-solving ideas...), Creative Thinking.

Has the Green Hat been used effectively in the last 2 years with regard to this Covid Pandemic?

The answer is simply NO. NO. NO!!!!!

Have you heard of anyone attempting to generate creative, valid, effective, solid ideas addressed to: mitigate, lower, or better stop altogether (target: 0 cases) this Covid-19 spread? NO, NO. NO!!!

Or: and what if.... and if we just would do..... and what else, how else, when else....

Nothing. Zilch.

Scientists, Thinkers, Philosophers (not to mention: Politicians etc.) and the like, have used only, or mostly, the Hats that most fit them: White (but only according to their know-how and, generally, mixed-up with the Red Hat), Black (as much as possible), Yellow (abused) and Red (mis-used)....

So: WHO has used the Green Hat in a valid, constructive way?

NO-ONE, that I know of....

BLUE HAT

BLUE HAT

Like the sky, the Blue Hat is all over the other thinking modes (or styles): it represents "overall thinking", "rational thinking", "co-ordination thinking".....

Who should use the Blue Hat?

Whoever is at "the top", "the Head".....

Who is - in this Covid case - at the top or at the head?

Well, it is (or should be - pardon me the coincidence) WHO, or the World Health Organisation.

Well, have WHO used well the Blue Hat in this Covid issue?

I prefer to give no answer.... I leave it into your hands.....

Surely, apart from providing (useful?) statistics and (valid?) guidance, after 2 years we are still back at square one (or worse...).

My dear friends, I wanted - on purpose - to be concise. So, I stop here.

Would Edward De Bono be proud of Human Kind's styles of Thinking? I suppose: no.

All the best, keep well, keep sane and safe (as everybody says), wash your hands, wear a mask, keep a safe distance....

And, hopefully, have a wonderful Holiday Season!

credits

Acknowledgement and a Tribute to:

Edward De Bono and his famous book The 6 Thinking Hats

download this article

|

Lean and Africa

by Carlo Scodanibbio

Every year I am based for about 6 months in Africa (Cape Town, South Africa) and 6 months in Europe (Malta).

Because of this migratory style, I happen to be lucky enough to notice changes - both in Europe and in South Africa.

What do I notice in South Africa?

Primarily, one phenomenon - which is the common denominator of several consequences.

The phenomenon in argument is an ever-increasing level of Complexity and Bureaucracy.

Certainly - one might argue - this is general: it's happening all over the world....

But in South Africa it has a very peculiar character: it is considered normal and, as such, well acceptable.

Let me give you a couple of examples:

- Banks. A Banking system that years ago was simple, functional and highly customer-oriented, has become over the years so complex, so full of forms to be completed, so full of redundant security measures, and so full of complex IT Systems, that the net result is: more time (for the customer - for whatever transaction) - more aggravations (in terms of documentation to be produced) - and very little customer-friendly (customers have been transformed from Mr X or Ms Y to Mr/Ms Account Number and/or ID Number).

- Insurance Companies. Years ago, it was a pleasure dealing with Insurers or Brokers for a claim or whatever transaction: the system was customer-driven, effective, efficient, fast. Nowadays it has become a pain in the neck: complex documentation - inflexible (strict clauses with no exception) - generally much slower in response time - and "take it or leave it..." attitude.

- Private Service Providers and Retailers. Similar considerations: strict procedures - poor customer attention - less service (even if at times camouflaged with formal, pre-baked greetings sentences....)

Well, I am talking of South Africa. With confidence that much of the sub-Sahara Africa is going through a very similar phenomenon.

What is going on?

We all know that the entire world has become more complex. But what about Bureaucracy?

Generally speaking, Bureaucracy is a way of being in control of processes that have been arbitrarily fragmented: every process is composed of activities executed by people, machines or combination.

A fragmented process is one in which each activity is independent from the others, and executed by a single-skill/single-function person or machine. Process fragmentation has been invented over 2 centuries ago by Adam Smith, then perfected by Frederick Taylor. That was the First Industrial Revolution, based on high, localised, activity efficiency (Labour Division principle).

Bureaucracy, in such system, is a necessity: control of a fragmented process must be based on rules and procedures (the glue that holds together bits and pieces of a process....).

So why is Bureaucracy increasing - with particular accent in Africa?

Because of a choice - the choice is between two avenues:

- The "traditional" choice. In a nutshell: "...let's stick to traditional, proven principles, and enhance process fragmentation, single-skilling/single-functioning, and top-driven control.... this will create "jobs" for little-skilled and/or unskilled people in the rather short term....."

- The "lean" choice. In a nutshell: "...let's embrace modern principles, and enhance value-adding processing, multi-skilling/multi-functioning, and gradually less top-driven control.... this will create wealth for everybody in the medium/long term....."

South Africa, and much of the rest of Africa, has (consciously? naively?) chosen the traditional option.

I do not intend - at all - to analyse the political reasons behind this choice: I am simply noticing a phenomenon and trying to illustrate its main consequences.

THE CONSEQUENCES - CONSIDERATIONS

- Yes, jobs - for the sake of creating jobs - have been created. Parking Marshalls have replaced coin-fed parking meters. Industry has assisted to the triumph of Single-Skilling/Single-Functioning. Roles such as "helper", "line feeder", "assistant", "labourer", "attendant", etc. have skyrocketed. One high-level manager recently told me "...now, only now, I realise that we have spent years de-skilling people, instead of re-skilling/multi-skilling them.....". So, jobs have been created - maybe. But wealth? It would appear that wealth is not increasing, but is rather going the opposite way.....

- Once trapped in "traditional" principles, the situation can be exasperated. It has been. Single-Skilling has been classified, codified, institutionalised: single-skill specialisation is a norm and a rule, at low-level and high level. I wanted to upgrade the software of my 3G modem and went recently into a branch of a famous Mobile Telephony Provider: the answer? "...oh, no, not here.... that can be done only in the XX Branch.....". In industry, there are very few "artisans" left - most of them are now pensioners. Years ago there were excellent "artisans", multi-skill, multi-ability, multi-function, capable of taking care of an entire repair/maintenance job, or a construction job, or.... Where are they now? Practically disappeared, replaced (ineffectively) by a number of single-skill doers, often interfering with each other, and with considerable idle time in their work-cycle schedule (pure waste).....

- Without even mentioning what happens in Public Offices, it does not take long to notice the increasing bureaucracy even in the Private Sector. Forms, procedures, rules... Years ago I could book a camping site over the phone - today I have to fill, sign and email a form, and email as well proof of payment.... If I had a motor claim with my Insurers, they would immediately send an assessor who would inspect my accidented vehicle, fill a claim form for me to sign, authorise repairs there and then, and even get the insurers to pay the Panel Beater directly.... Nowadays I have to provide and email photos, claim form, scanned Police Report, supporting documentation including signed statement of events, etc. etc. plus pay for repairs and then fill, sign and email a "release form" to get refunded (less fat excess...)... and so on. These are signals of higher bureaucracy consequent to process fragmentation and no process-ownership.

- As such, Value to the Customer (a fundamental Lean principle) has decreased sharply. In terms of - as I was saying - more time, slower response, more aggravations. Plus, an ever increasing mass-communication approach instead of the lean "one-to-one" approach. Just think how the so-called Call Centres have mushroomed...

- Unfortunately, there are also other signals. One rather strong signal is that - generally - sense of "responsibility" has dramatically decreased. Responsibility for own work and its outcome. I brought recently my car for a valet service. On collection, I noticed the aerial top was missing. They looked and searched everywhere. Nothing. So, "...sorry, Sir, it's not here.... most probably this car came this morning without aerial top....". Impossible. That aerial top doesn't fall accidentally - it must be forced out. Well, end result: "...not our fault... besides we display a prominent notice that we are not responsible for items lost in these premises.....". Shocking? I brought the same car after a few days to have the aerial top replaced (at an exorbitant cost). And I did not bother to remove from the car a few parking coins I normally keep there to tip.... On collection, no parking coins - gone. I pointed it out, not for the value of those coins, but as a matter of principle. Answer: "....when you sign a job card, you should notice that we are not responsible for any valuable left in the vehicle..... Apologies.... But, you know: we are in Africa.....". Which leads to the next consideration.

- Finally, the "feeling there is nothing that can be done.....". Lack of confidence in the future. A diffused feeling. One can sniff it, one can hear it, one can see it.... It's like to say: "....why care? what for? there is no future....". Bad, bad news. In the past few years, every time I presented a Lean course in South Africa, I heard - without exception - some delegate coming up with comments such as "...brilliant course.... very nice principles.... BUT, can it be done in Africa?....."

CONCLUSIONS

Would Africa benefit from embracing Lean principles?

The answer is definitely YES!

Can Africa do it?

Of course it can. It has been done. It can be done again. Several clients of mine (from the Private Sector) still keep telling me "....fortunately we decided to go lean... shouldn't we have done that, today - in this turbulent economical situation - we would have been dead.....".

I agree, the future scenario does not look brilliant - at all. The way ahead is very "rocky".....

And yet, with positive confidence, with determination, with drive... it can be done.

All the best, Africa!

download this article

|

Covid-19 and the future of "Lean"

by Carlo Scodanibbio

Late 2019. The world changed: once more. Dramatically. Irreversibly.

The Corona Virus, or Covid-19, has given an unprecedented spin to this world of ours. This Pandemic has made obsolete almost everything we knew, we believed in, we were used to.

The overall impact of Covid-19 - to date - is immense: scientists, economists, politicians, thinkers, church leaders, philosophers and psychologists (among others) are trying hard to understand, to explain, to foresee, to recommend, to take measures.... it's their duty, or their job, or their passion.

It's not within the scope and style of this web site to add comments or explanations to the billions we hear on a daily basis with regard to Covid-19.

However, it is certainly within the scope of this web site to make suggestions and recommendations to people in Industry about how to tackle the enormous challenges of the years to come.

In line with my Philosophy, Vision and Mission - I, Carlo Scodanibbio, strongly believe that, sooner or later, this Pandemic will be over: no doubt about.

Human Kind has gone through the most incredible difficulties for thousands and thousands of years: all of them rather successfully overcome.

Human kind will make it also this time, once more. It's just a matter of time.

However, the world will never be the same as before: after Covid-19 and all its by-products, the challenges for all Industrial & Business Organizations will be tougher than ever. Only the fittest, the best, the Leanest will survive and will be in a position to tackle the difficult years ahead with a high level of confidence.

BUT: NOW it's the right time to prepare.

Before Covid-19 there wasn't one single Enterprise or Organization that could proclaim itself 100% Lean. Although there were thousands and thousands, world-wide, that had made enormous progresses in the Lean road.

And after? After Covid will be a thing of the past?

There will be no such thing as "....hah, back to business....." or "....business as usual....".

The law of "Survival of the fittest" will apply in full - no doubt about. It's well verified at the date of releasing this announcement. It will be even more after.....

Who will the Fittest be?

The Fittest will be those Enterprises and Organizations that will be ready to deploy in full all Lean Management/Lean Thinking principles in a novel way.

Why?

Because after this tremendous change brought-in by Covid-19, only those who will be ready to deliver to Clients - in a very creative way - the highest Value with minimal/nil Waste may hope to survive - to prosper - and even to excel.

BUT: while Lean Principles will always be the same, the adaptation of those principles to a world that will be radically changed will require a high degree of creativity and commitment/involvement by ALL.

After Covid-19 era (assuming there will be a definite "after"), the world will continue to change at an unprecedented speed and with novel features in continuous evolution: "stability" will simply be non-existent.

Markets will change their features rapidly and frequently. Social issues, factors and parameters will be in continuous evolution. The impact of climatic changes may become unbearable. Technology will also upgrade to levels unknown today. And so on.

Therefore: strategies, approaches, and styles of operations will need to be in continuous adaptation/evolution accordingly.

This will command a combined effort, top-down driven but with the highest bottom-up contribution: all resources, all brains, all spirits will need to be mobilised.

Because only in this way, Organizations will be able to generate timely responses suited to novel, unforeseeable circumstances.

Ideas will win. Speed will win. It will be everybody's task to come up rapidly with simple, effective, inexpensive ideas suited to spot and generate opportunities, overcome difficulties, create new operational dynamics....

It won't be easy: we are not much used to it. It will be challenging: a new breed of people will be required. It will be tough: "traditional" management will need to quit, replaced by a new style "participation management".

NOW is the right time to prepare for it.

NOW is the right time to make ALL conscious of the most basic existential principle: "each one of us is fully responsible for his/her life - no-one else is".

NOW is the right time to sensitize ALL to change and to the need for change and continuous adaptation.

NOW is the right time to instil in everybody's mind concepts of commitment and participation/involvement.

NOW is the right time to educate and train ALL in basic Lean principles.

NOW is the right time to explain to ALL basic principles of Creative Thinking and generation of Ideas.

NOW is the right time.

download this article

|

Lean Management: the origins, the principles, the approach

by Carlo Scodanibbio

lean management: foreword

Lean Management is primarily an Industrial and Organisational philosophy.

It all started in the era of Just in Time (more ») and the Toyota Production System (more »); it all started in the Manufacturing Industry.

That's when TPM - Total Productive Maintenance (more »),

the 5S methodology (more »),

Flow Production (more »),

One-Piece Flow,

Cell Manufacturing (more »),

the Kanban Method (more »),

Poka-Yoke (more »),

Total Quality Management (more »),

Kaizen,

Total Employee Involvement (more ») and all other allied disciplines were developed.

It started in order to increase competitiveness through Manufacturing performance. Japan, where it all started, succeeded gloriously in this regard.

The Western Industry, slowly but surely, followed the Japanese approach, perfected (and "westernalised") the Japanese approach, and Lean Manufacturing (more ») was created ('90s).

Having noticed the benefits achieved through Lean in the Manufacturing Industry, also the Project/Construction Industry copied/pasted/adapted lean approaches, transforming the classical but well-dated Project Management discipline into Lean Project Management (more ») and Lean Construction Management (as well as Lean Contract Management) (early 2000...).

Simultaneously, many Consultants and Industry experts started understanding the power and benefits of Lean, realised that the ultimate factor making the difference between the "traditional" and the "lean" approach was THINKING (as only through innovative thinking could lean principles be deployed in different industrial sectors), and created the terminology Lean Thinking (more ») as global approach to lean transformation.

Lean Thinking was just a bit later (from +-2005....) applied also to the Service Sector, generating lean disciplines such as Lean Process Management, Lean Process Engineering and several others.

Today, we consider Lean Management as the big umbrella under which all lean disciplines and methodologies applied to various Business/Industrial Sectors fall.

In conclusion, the Lean approach has changed the overall operational and strategic approach in all Business/Industry sectors (Private and Public). Why?

Because there was a need for it. Why?

Because the World had changed....

lean management: the origins

Business People, People in Industry!

The World has changed!! Dramatically! Irreversibly! A drastic change.....

What has changed?

Everything: the world has changed from an economical, financial, social, technological, commercial..... etc. point of view.... ALL has changed: a real, solid change....

When did it change?

No-one knows.... in fact, the world has always been changing..... but slowly, gradually.... until the speed and the acceleration of change increased drastically.... and when did it happen? Once again, nobody can say.... all they say - hilariously - is that most probably, when the change took place, it was at about 2:00 or 3:00 am in the night.... and everybody was fast asleep at that time, so the change went un-noticed.....

In the next day, most people - few exceptions - woke up as usual: "...hah, another day, things as usual, business as usual....."

But it wasn't so anymore.....

Let's correlate this phenomenon of "change" to Industry and Businesses performance.

How have they reacted to change? Most of them: little - or none. Some of them: considerably. The first in the classroom: brilliantly. But they are, generally speaking, the exception....

Most Businesses, Organisations (Private and Public), and Industry in general are still acting today according to old principles, approaches, rules.... and even dogmas, that should be considered obsolete. Instead, they are still alive and kicking.

If you can think back 50, 40 and even 30 years ago, things were really different: the world was relatively "stable", "predictable", almost "static" - one could see horizons very far away.... - Organisations used to carry out "long-term" (10 years and even 20-30 years) "strategic planning" projects..... and they would even implement such projects (with all necessary touch-ups, obviously....).

And 30 years ago? Turbulence was starting: the market was opulent but well saturated.... competing and succeeding was becoming harder and harder.....

And 20 years ago? Even more turbulence, fierce competitiveness, harder and harder....

And 10 years ago? Tough, tough, tough...... a fight for survival.....

And today?????

And the next year????

And the next 5 - 10 - 20 years?????

Possibly, no-one knows....

The only thing we know - and possibly more and more people in Industry start realising it - is that we cannot carry on fighting with obsolete guns and ammunitions....

Over the last 50 years, in order to increase fighting power, an extraordinary number of disciplines and techniques have been invented by Consultants, pipe-smoking University Professors, Industry Experts, and the like.

The aim: increase operational and strategic performance through a number of initiatives directed to make people in industry perform better, more efficiently and more effectively, as well as to improve certain specific areas (for instance: the Quality "domain").

To mention just a few:

Management by Objectives - Effective Leadership - Motivational Talks - Diversification - Z Theory - Situational Leadership - Effective Communication - Zero-based-Budgeting - Decentralisation - Team Building - Self-Directed Work Groups - Management by Exception - Dale Carnegie techniques - Interpersonal Skills - Quality Circles - Search for Excellence - Restructuring - Interactive Management - Portfolio Management - Matrix Organisational Structure - Quality Control - Quality Assurance - ISO 9000 - 6 Sigma..... and even One-Minute Managing......

And the results?

Well, let's be honest, all of them are great disciplines, and all of them (including the famous "One Minute Manager" ) have somehow contributed to increase some aspects of organisational performance. But generally: localised - or "per department" - or marginally - or.....

In other words, they have contributed to improve (actually: to organise in a better, structured fashion) "some" aspects or parameters of performance.....

However, although most or many of them were intended to address ALL aspects of performance, in their practical use the effect has been to improve only some area, be it the Human Resources kingdom, or the Quality area, or the co-ordination of inter-functional management, or....

But: overall organisational performance has generally improved only marginally through adopting - even by the book - those disciplines.....

In certain cases, improvement has not only been marginal or localised, but even "spurious" (i.e. one or some department functioning better, but overall output/performance little or no improvement).....

Why?

Because none of those excellent Disciplines has actually aimed at touching or reviewing the ultimate core of the organisational performance: the Organisation's "DNA"!

The fact is that:

.... we have gone into the new millennium with styles and approaches to overall organisational performance conceived long time ago (well over two centuries) by Adam Smith (the rather famous Division of Labour principle) and perfected during the last century (by Frederick Taylor with his Scientific Management System and - most intriguing - by Unions all over the world, with their aseptic and almost "freezing" approach to personnel performance....

Such style and approaches - perhaps adequate until the mid '90s - are, unfortunately, no longer suited to face the tough challenges of the years ahead....

ADAM SMITH

Adam Smith was a Scottish economist, philosopher and author as well as a moral philosopher, a pioneer of political economy and a key figure during the Scottish Enlightenment, also known as ''The Father of Economics'' or ''The Father of Capitalism''. (Wikipedia)

Adam Smith was a Scottish economist, philosopher and author as well as a moral philosopher, a pioneer of political economy and a key figure during the Scottish Enlightenment, also known as ''The Father of Economics'' or ''The Father of Capitalism''. (Wikipedia)

Smith wrote two classic works, The Theory of Moral Sentiments (1759) and An Inquiry into the Nature and Causes of the Wealth of Nations (1776). The latter, often abbreviated as The Wealth of Nations, is considered his "magnum opus" and the first modern work of economics. (Wikipedia)

The Wealth of Nations is really worth to read (just Google-search for it and you will find the full text).

Smith was a real genius. In a period of time in which there was no industry at all (but only craftsmen), Smith visualised that the future wealth of all nations would come from industry!

And he went one step further: through the rather famous example of the "pins factory" Smith explained in clear terms how industry-to-come should be organised operationally!

Smith explained that a work process - such as that of fabricating "tailor pins" - should be subdivided in a number of single, elementary tasks (or steps), and one person (one labourer) should be assigned to each individual task that he would carry out repeatedly.

Like to say - in the tailor pin case - that one person would draw the wire; another person would cut it to size; another person would straighten it; another person would sharpen the one end of the pin; and so on..... - as opposed to one person executing alone all the necessary tasks in the process (craftsman style).

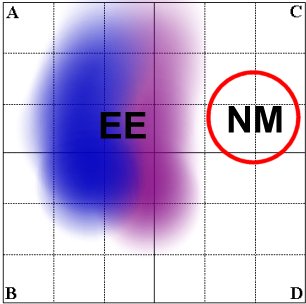

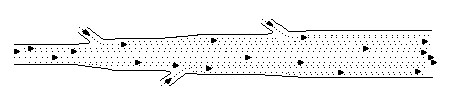

The concept is schematised here below:

According to Smith, a "fragmented" manufacturing process like in the example offers 3 very distinct advantages:

-

By carrying out repeatedly the same task - especially by "exerting" himself a bit, as Smith says - a worker will master it: efficiency will become very high

-

Should one day - for any reason - a labourer not turn up for work, it will be rather easy to assign that task to any other worker: because of the simplicity of the task itself

-

And: by providing dedicated tools and simple, well-chosen equipment to mechanise each task (or part of it), efficiency in each workstation will increase even further....

Smith was right.

When his principle (the Division of Labour principle) was deployed (never mind in a tailor pins factory) in the Automotive Industry a few decades later, the principle proved to be very valid: high efficiency, high productivity (the famous "rope and winch" assembly chain......).

Although Smith's Division of Labour was conceived primarily for the Shop Floor of a Manufacturing Factory, the principle was then extrapolated and expanded in its field of applicability.

Starting from the early 1900s, Alfred Sloan, general manager of General Motors, having deployed Smith's principles on the shop floor with success, tried hard to expand Smith's concepts. And he had an idea: why not apply the Division of Labour principle also to Management?

Starting from the early 1900s, Alfred Sloan, general manager of General Motors, having deployed Smith's principles on the shop floor with success, tried hard to expand Smith's concepts. And he had an idea: why not apply the Division of Labour principle also to Management?

After all - in a growing industry - having simple, generic "management" was not, in Sloan's opinion, the most effective solution....

According to Sloan, "management" should be "sub-divided" into specialised/dedicated branches, each taking care of one area of "management"... besides "General Management", there should be, for example:

Administrative Management

Financial Management

Operations Management

Maintenance/Plant Management

Sales Management

Service and After-Sales Management

and so on.....

And, voilà, Functions were invented!

And, voilà, Functions were invented!

The principle of "division" and "fragmentation", conceived by Smith for the Shop Floor, now had been transplanted upstairs, touching the very Organisational Structure of an Industrial concern.....

Does it ring a bell?

Does it remind of something still alive today?

It does, indeed!

The rationalisation of the "upper floors" (the Management structure) went further on:

Frederick Taylor, Engineer and Consultant, had already created his "Scientific System" (also known as "Taylorism").

Frederick Taylor, Engineer and Consultant, had already created his "Scientific System" (also known as "Taylorism").

The Scientific System went full steam into the Management Structure organisation.

According to Taylor:

Due to market expansion and growing complexity in Manufacturing, Management had to be structured "scientifically" adopting healthy principles of PLANNING and CONTROL.

But in order to Plan and Control effectively, Management had to be organised in Levels, whereby each Level would plan the work to be carried out by the lower level and then control that the work had actually been done according to plans.

Levels - according to Taylor - would re-organise Management's role in a much better shape: therefore, above the "Shop Floor" Level, there would be a Frontline Level: in charge of fine-planning the Shop Floor works and control the validity of the output.

And above the Frontline Level, there would be a Supervisory Level.

And above a Middle-Management Level.

And above a High-Management Level.

And above the General Management Level.

With Managers at each Level planning and controlling the activities of the just-below Level - and each Level with a different horizon and style of intervention, but with all Levels aligned according to vision, policies, objectives, targets, etc. set at Top Management Level.

And, voilà, here is the Pyramid taking shape!

And, voilà, here is the Pyramid taking shape!

Does it ring a bell?

Does it remind of something still alive today?

It does, indeed!

But there is still an essential ingredient missing, essential to make the Scientific System gearbox turn and function smoothly and effectively.

The missing ingredient was suggested by the Railways!

Do you remember the famous movie "Once upon the time in the West"?

Do you remember the famous movie "Once upon the time in the West"?

It was showing an American Railway being constructed (+-1860s) in the Far West.....

At those times, railways were single-track. Therefore the possibility of 2 trains colliding with each other was very high.....

In order to prevent accidents, the Railways introduced basic, golden RULES:

- such as signals (stop-go)

- and - most important - marshalling tracks at crucial points, so that a train could be parked in that track while another train, coming from the opposite direction, could pass.....

RULES were the secret!

And Engine Drivers main responsibility was to respect all Rules!

Surely, RULES are needed everywhere, including in an Industrial concern!

So - together with PLANNING and CONTROL - RULES became another essential ingredient of the Scientific System.

Which makes sense: Personnel, at all Levels, must adhere to and operate according to Rules....

In Industry in general, under the general term RULES, gradually were introduced:

- Policies

- Regulations

- Procedures

And Roles, Positions, Job Descriptions.... and Work Instructions, Standards, Specifications, Timetables, List of Duties..... and, and.....

Does it ring a bell?

Does it remind of something still alive today?

It does, indeed!

HIERARCHY had been invented!

And something else. As a by-product of the combination of LEVELS and RULES, a novel phenomenon originated and gradually grew and grew: BUREAUCRACY!

Bureaucracy, in simple terms, means that - in order for something to happen - a request must be made: that request (for a decision to be made, or for a green light, or.....) has to climb possibly several Levels, until the right switch is triggered and the request is fulfilled. Then, same routing down the various Levels up to reaching whoever originated that request - obviously according to certain Rules and Procedures as applicable to the case..... which may contribute considerably to slow down the wanted output......

Surely, neither Smith, nor Sloan, nor Taylor planned or wanted Bureaucracy to materialise.

But it was born, and grew over the next decades....

Although one might think that Bureaucracy was and is a phenomenon confined to/specific of the Public Sector, it has actually been and is still today well alive and kicking also in the Private Sector....

Finally, one last comment: over the last decades, Unions have greatly contributed to "maintain" (almost "freeze") the Smith/Sloan/Taylor Model. Why?

Because of Unions' passion for Roles, Positions, Job Descriptions, Careers Schemes, etc.etc.

the first industrial revolution

The above story describes the origins of Industry: yesterday's industry was born....

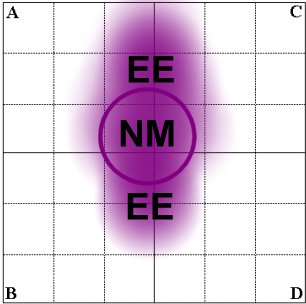

The FIRST INDUSTRIAL REVOLUTION, as it was called, can be schematised as follows:

The above story also suggests the origins of Lean Management.

Because, not only yesterday's industry was born - also today's industry was born!!

One may ask: "why also today's industry"?

Well, let's be honest: apart from a number of touch-ups over almost one century, the way Industry, Businesses and, in general, most private and public Organisations are structured - still today - does not differ much from the Smith/Sloan/Taylor model!

Still today, Division of Labour, Functions, Management Levels, Planning, Control, Rules, Procedures, etc. etc. are there!

Fragmented Processes are still there!

And Bureaucracy is still there!!!

One may also ask: "and so, what is wrong with this model"?

No, not much wrong, for the time being..... for the time being, let's just say that this model is rather dated...... (to say the least).

It was conceived over 2 centuries ago - perfected in the last century - to work well in the last century!

And it has worked very well!! Especially after the Second World War.... and it had its glorious time in the '60s and the '70s (the era of mass production.....).

But it started showing some deficiencies already during the '80s.... more in the '90s....

And in the new millennium? Big question mark.

Lean Management originates from a deep analysis of the First Industrial Revolution Model, highlighting all its deficiencies first, then coming to the rescue (see below)!

the deficiencies of the Smith/Sloan/Taylor model

THE LAWN MOWER

In all my Lean training courses, I make the example of the Lawn Mower. The story:

In all my Lean training courses, I make the example of the Lawn Mower. The story:

So, there has been heavy rains (climate change, tropicalization.....), and the lawn in the garden needs a solid mowing. If you are a rich man, you have a gardener who will take care of the mowing task.... but if you are an ordinary man in the street, you will have to do the mowing yourself - not your wife, not your kids, but you, the man in the house.....

When? Not during the week, because you work.....

Not on Sunday, family day.....

Not on Saturday morning, shopping with wife.....

So, what is left? Saturday afternoon!

But on Saturday afternoon there is cricket (or football, or tennis.... whatever your favourite sport is) on TV!

So, if the mowing must be done, it must be done early Saturday afternoon, and quick! Because cricket starts just now.....

So, you fetch the lawn mower (petrol engine driven), start it, and.... GO! Go as fast as possible, it's late already!

So you push the lawn mower at full speed through the thick, tall lawn.... BUT: if you push it too fast, the engine will stall! So, pull it back, let the engine breathe and rev-up again, and then push again like mad!

But the poor engine will stall again: it cannot cope at fast speed..... Why?

Because there is a limitation to the speed at which the lawn mower can advance forward and mow the loan properly: the limitation is given by the HP of the engine! More than so much it cannot do!

And I keep saying:

A "Traditional Enterprise" is like a Lawn Mower: more than so much it cannot do! In terms of output, results, effectiveness.....

Because also a "traditional" Enterprise (or Organisation) has a limitation! The limitation is imposed by the features of its Organisational Structure: the way it is conceived, the way it can act, its overall "capacity", etc. etc.

That is its DNA! Equivalent to the Horse Powers of a Petrol Engine.

Over many decades we kept discovering the "limitations" (or deficiencies) of Organisations built and structured around the Smith/Sloan/Taylor Model: frequently or regularly, the Organisation was "stalling", it wouldn't deliver the desired output and results, it could not run smoothly, there was "hiccup" processing, and the like.

And what have we done?

We have kept increasing the Organisation's HPs, in the hope it would perform better.....

How in practice?

Perhaps another Function? Or another Department? Or more Personnel? Or more qualified Personnel? Or, or.....

Or a new Position? Or new Roles (Assistant, Executive, Executive Secretary, Deputy, Chief.....)?

Or more Planning (long-term, yearly, monthly, weekly, daily, hourly..... fine Scheduling.....)?

Or more Control (strict Quality Control, Statistical Quality Control, Quality Assurance methodologies, ISO 9000.......)?

Or more Rules (more Procedures, detailed Procedures, stricter Procedures, more Work Instructions, Check-Lists.....)?

Or more Technology (more Machinery, more powerful Equipment, better Tooling, powerful IT Systems, MRP, MRPII, ERP.......)?

Or more initiatives/actions on Human Resources (Motivational Speeches, Motivational Techniques, MBO, MOBOII, Team Work, Team Building, Self-Directed Work Groups.......)?

The list of initiatives undertaken in order to revitalise an engine that was stalling could be endless. And yet, decades after decades, the "engine" shows some stalling..... the DNA doesn't seem to be adequate.....

And so, since the Climate Change and Tropicalization bring more rain and the lawn grows thicker and taller, the Lawn Mower Engine HPs should be increased indefinitely.

Likewise, since the World Change keeps increasing more rapidly and almost exponentially, the Organisation/Enterprise DNA is never adequate and should be revised and touched-up indefinitely.

BUT: it's just a matter of touching-up? Of tuning, of revising? Or has it become a matter of a comprehensive reviewing, starting from square one again??

About THE "SYSTEM"

There is a word widely used, often abused: the word system. You can hear it very often: at a bank, or at an Insurance Company branch, or at a Travel Agent, or at an Info Centre..... ('.... sorry, Sir, today the "System" is a bit "slow", it takes time....... - or..... the "System" is "down", it will take a bit to reset.....').

Generally, the Bank or Insurance Branch officer making such statement has a very relaxed attitude - meaning "...excuse me, Sir, it's not my fault..... it's the System.......".

Yes: the System is slow or the System is down. It happens, often.

Here we are however referring to an IT System.

But something very similar happens in most Organisations/Enterprises, and rather often: the System is slow or the System is down.

It is the Organisational System that is "slow" or is "down".....

Why?

For one main reason: "a System Output cannot exceed the limitations imposed by the System itself"!!

Like to say: "do not expect results greater than what the System allows!

This is a well confirmed and well verified truth, seen in Industry for decades, but never analysed nor investigated to deep extents.

The first, serious attempt has been made - very successfully - by Lean methodologies (see below).

But before describing the Lean analysis of and approach to "Traditional" Systems' deficiencies, let's extract another very important truth regarding the System itself:

"Personnel Performance cannot exceed the limitations imposed by the System!"

This statement, although well understandable, requires a few explanations:

- Rules, Control, Procedures, Job Descriptions, and the like, obviously put somehow a limit to the results people can produce: in terms of Output, Time, Quality, etc.

- actually, Control (especially Quality Control) may have the detrimental - even if unwanted - effect of People lack of commitment to Quality, to goodness of own work, to pride for own work, etc. (".....why should I care too much? If any problem, it will be up to the Quality Controller to reveal it.......")

- Hierarchy does not contribute to People Motivation

- Nor do all other typical parameters of the "traditional" model: Levels, Rules, Control.....

And finally,

About the LABOUR DIVISION principle

Smith's concept of Labour Division was very right and very pertinent for the times in which it was conceived (and several decades more.....).

It was right for the culture, the level of education and the approach to work of people of last century, possibly until the '70s.....

It was also very right and valid in an era of unsaturated market, of mass production, of limited competitivity....

But after the World changed it rapidly became obsolete.....

Let's deep-analyse with Lean spectacles what happened and still happens in a Shop Floor organised under the Labour Division principle:

Firstly: the concept of high efficiency at each processing station (manned by one individual).

No doubt, a repetitive, simple activity backed by the right tooling/equipment can be extremely efficient.

However it carries a side-effect that Smith did not consider at all: the negative impact on people and their spirit/motivation, in terms of frustration, stress, boredom, lack of interest for work, distraction........

Which, when they reach certain levels, may cause errors, mistakes, poor quality, mishaps....

And, no wonder, gave origin to the famous TGIF - Thanks God Is Friday "motto".....

Surely, Smith did not think of that. But nowadays (actually from already a few decades), this side-effect is well known.

And let's analyse further. Let's see what happens around and in-between processing stations:

Never mind a tailor pins factory, let's consider any "traditional" manufacturing Shop Floor organised according to Division of Labour principles.

Let's consider a real factory. A "traditional" factory is generally laid-out job-shop style, i.e. there is (for instance) a Store, a Machining Department, a Welding Department, a Pre-Assembly Department, a Final Assembly Department, a Packaging Department, and so on..... - and each Department (or Job Area) is in a convenient location in the factory, with some spacing in between; although in each Department there are Single-Skill/Single-Function Processing Stations (as per Division of Labour principle).

This involves that each Processing Station must be fed with materials, components, consumables, ancillaries, etc. necessary for production - and also involves that the output of each Processing Station must "somehow" be "transported" to the next Processing Station.

-

Between one processing station and the next, we find: handling (off-loading previous processing station - loading next processing station; plus moving, lifting, lowering, placing, transporting) - and storage (materials, components, work-in-process, quasi-products.....), in the form of parking, palletizing, positioning.....

-

"Around" processing stations we also find: handling, storing, inspecting, supervising.....

-

In some processing stations (or just out of them) we find: inspecting, controlling, quality controlling, checking, counting.....

-

And in some processing stations we may find: errors, mistakes, producing defects, producing rejects, separating defects and rejects from good product......

-

As a consequence, around processing stations, we may find: dealing with defects and rejects, assessing causes of defectiveness, doing the necessary reporting.....

The list could be very, very long.....

Surely, Smith did not even think of such consequences, and many Manufacturers - although noticed these "extra" activities correlated with a fragmented type of processing - simply lived with them for decades, considering them "normal" work activities.....

Even worse, many manufacturing managers, in a "raptus" of Taylorism, perfected to extremes those kind of "extra" activities: so they invented the Internal Transport Department, the Materials Feeding Department, the Quality Control Department...... and created titles such as handler, fork-lift driver, crane operator, cartonizer, palletizer..... and inspector, supervisor, foreman, controller (quality - production)..... with detailed job descriptions for everyone....

After all, until the World changed, Clients were paying for all those "extra" activities!

Does it ring a bell?

Does it remind of something still alive today?

It does, indeed!

FRAGMENTED PROCESSING

And let's also have a look at the upper floors: at the Pyramid and its contents.

Because also within the various Functions and Levels we can find fragmented processes!

One simple example: a Client's request (a query - additional information - a commercial dispute - a complaint - a technical question - etc.), after landing at destination, may need to be "processed" with the intervention of various officers/employees in different Functions and at various Levels, before the necessary "output" is generated and transmitted back to the Client....

One simple example: a Client's request (a query - additional information - a commercial dispute - a complaint - a technical question - etc.), after landing at destination, may need to be "processed" with the intervention of various officers/employees in different Functions and at various Levels, before the necessary "output" is generated and transmitted back to the Client....

Although this might be typical of "large" "traditional" Organisations, also in smaller, "traditional" Enterprises something similar takes place: a number of different persons, each handling and taking care of a "bit" of the entire process, get involved to "process" their "bit": with time delays, "transport" of information between processing stations, etc. etc.